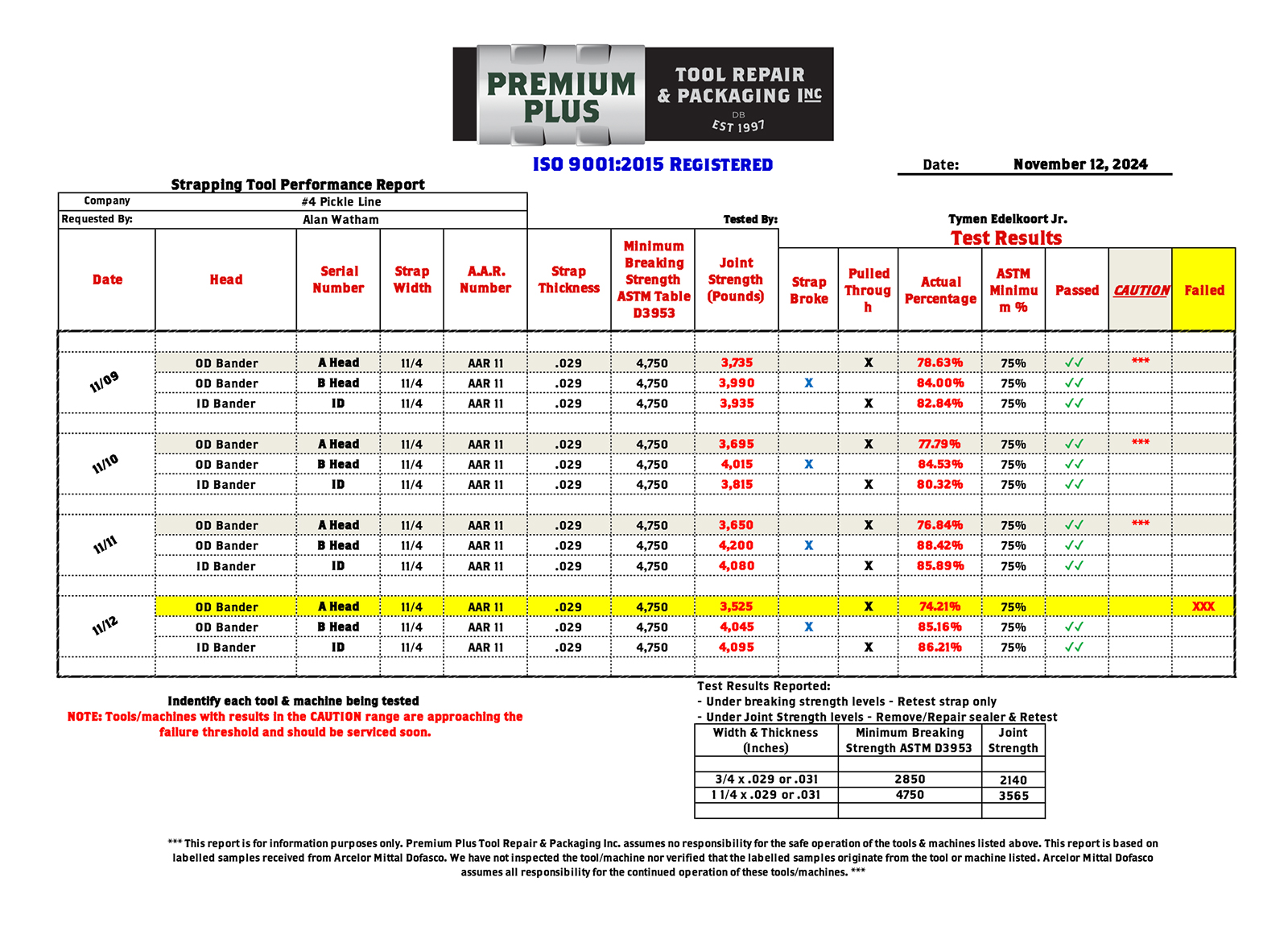

SEAL JOINT TESTING

WE OFFER SEAL JOINT TESTING SERVICES

At Premium Plus Tool Repair & Packaging Inc., we offer industry-leading seal joint testing services to ensure the integrity and reliability of your strapping tools and materials. Here’s what sets our testing apart:

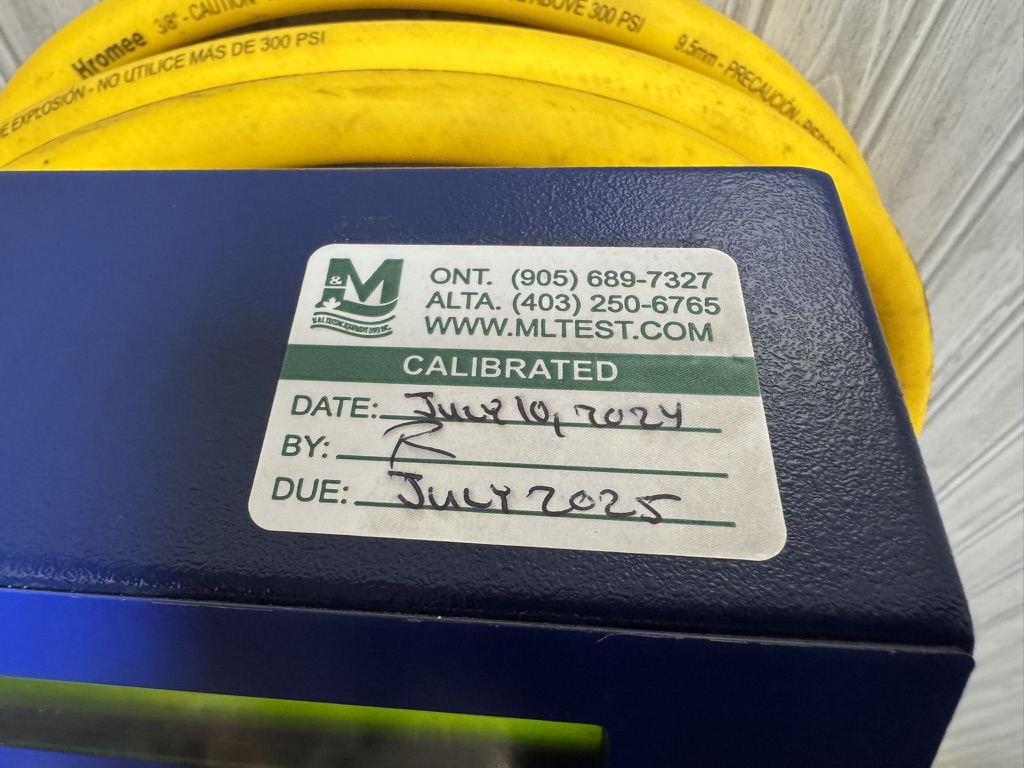

Our testing is performed using the latest standards – both ASTM D3953-15 for steel strapping and ASTM D3950-17 for plastic/PET strapping. We ensure every test meets stringent requirements, delivering results you can trust.

We adhere to the highest quality standards as an ISO 9001 Registered company. Our testing machines are tested and calibrated annually, guaranteeing precise and reliable results.

Why Choose Us?

Comprehensive Pull Testing for All Seal Types

Whether it’s single notch, double notch, or sealless joints, we test all seal types to ensure they meet or exceed industry standards.

Proactive Tool and Machine Maintenance

Seal joint testing is an excellent barometer to identify if your tools or machines need repair. Like brakes in a car, wearing parts in your equipment can degrade over time. Through frequent and consistent testing, you’ll gain insights into:

- The rate of wear on your tools and machines

- When to schedule repairs, reducing the risk of unexpected downtime

Detailed Reporting

Send us your samples via courier or drop them off in person. We’ll provide a comprehensive, easy-to-understand report with clear results and actionable insights.

Every Tool Repaired is Tested

If your repaired tool seals, then you will see on your sales order and invoice the Seal Joint Test Result every time. This gives you a piece of mind that your repaired tool exceeds minimum standards when it’s returned to you.

Beyond Seal Joints: Strap Testing

We also test virgin strap pieces to verify critical factors such as:

- Elongation

- Thickness

- Break strength

- Proper breaking points

- Trusted by Industry Leaders

Reputable corporations like ArcelorMittal Dofasco, Taylor Steel, Nova Steel, Nelson Steel, and Itipack rely on our expertise for their seal joint testing. You can trust us too!

Get peace of mind knowing your strapping tools and materials are performing at their best. Contact us today for pricing!

SHIPPING INSTRUCTIONS

1

Strap Sample

Strap sample does not need to be under tension; you can simply seal two pieces of 12” strap together with your tool.

2

Size and Thickness

Let us know the strap size and thickness you are sending to us.

3

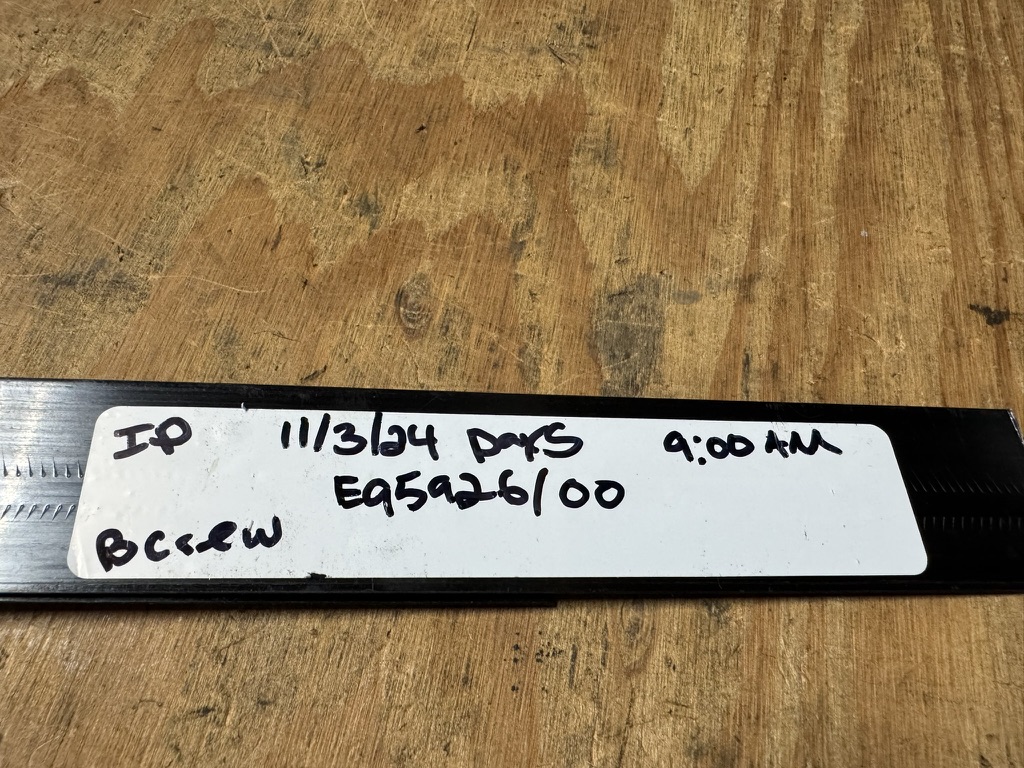

Label

Label your strap so it can be identified (tool/machine serial number, date, location within your plant, etc.). We will put on the report whatever you need!

4

Cut Your Strap

Cut your strop down to approximately 9”-11” on either side of the seal.

5

Cut the Overlap

Cut the overlap(s) down to 1/2” to 3/4” long

6

Ship

Ship it to us!

IMAGE GALLERY

CONTACT US

For further information, please get in touch with us!

"*" indicates required fields